We are Internet of Things Specialists

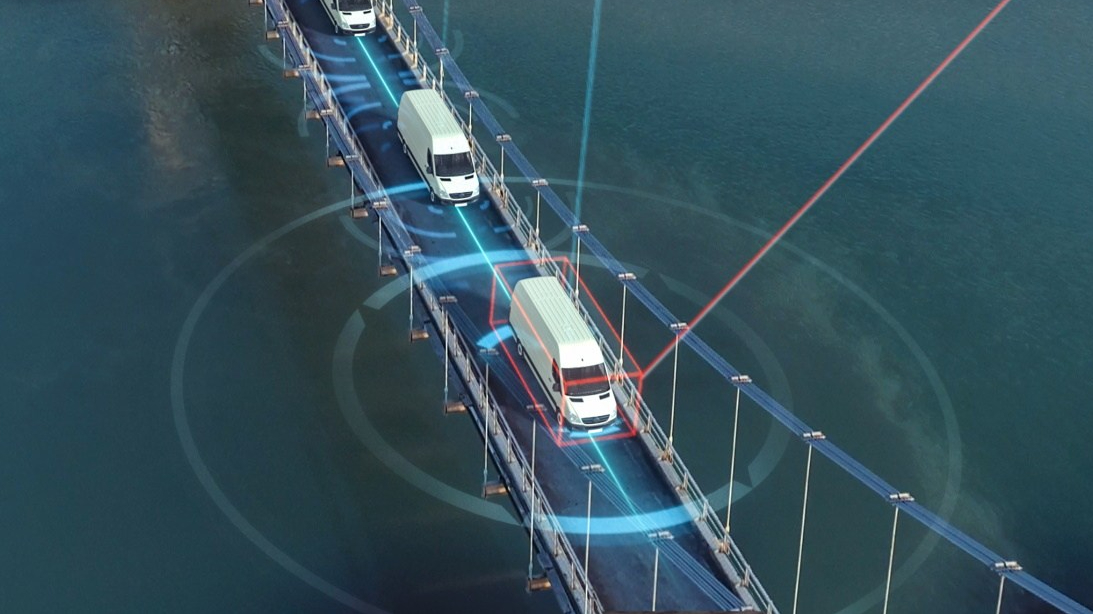

Acting as a gateway between physical things and the digital world, the Internet of Things offers companies tremendous opportunities to better understand their business operations and their customers. Esprida works with our clients to open or expand this gateway using the latest IoT technology, offering unlimited possibilities for insight and growth.

Our expertise covers the complete spectrum of IoT, from sensors, edge devices, and connectivity to IoT analytics, data visualization, security, applications and services.

Esprida has been integrating sensors into existing machines and systems, connecting devices, architecting IoT solutions, implementing pilot projects and providing analytics and insightful visualization to our customers since 2000. From retail kiosks and remotely managed printers to retrofitted manufacturing equipment and remote crop monitoring stations, we’ve been helping our clients retrieve “their” data so they can better serve their customers and improve their bottom line. We will leverage our 21 years of experience to help you plan and launch new IoT initiatives or enhance existing ones.

Advanced technology for a clearer future. This is Esprida.

Microsoft’s Azure IoT is a collection of managed cloud services and cloud applications that connects, monitors, and controls billions of IoT assets. It is a highly secure platform that can scale up in both the number of devices and scope of functionality. This makes it easy to move from a small pilot project to a full-scale rollout and add new features as your needs and vision evolve.

Our Microsoft partnership and experienced team of Azure consultants can help your business become more connected and stay ahead of the competition.

Why choose Esprida to develop your IoT solution?

We have 20+ years of experience developing remote management applications and 10+ years developing IoT solutions with customers in the retail, financial, government, manufacturing and agriculture sectors. No matter what level of experience you have deploying IoT solutions, our team has the expertise to take your IoT initiative to the next level.

Scalability

Using Azure Services and modular IoT architecture allows us to plan, develop, deploy and review features of the final solution and decide when features are ready to deploy into a production environment. This provides your engineering and support teams with hands on experience early in the project cycle; simplifying their solution ramp-up and providing valuable production feedback

Collaboration

We have developed a Lean IoT methodology to build IoT applications using an agile development approach that actively involves our customers. This provides early visibility into feature development, flexibility to prioritize features according to business value and predictable costs and schedule delivery. With this we can deliver a minimum viable product or first application version with a lean set of high-priority features within 3-6 months and release new features every 2-4 weeks.

Quality

We place a premium on an application’s quality from the very start of the project and focus on prevention and early detection of defects.

Security

We incorporate security in our designs using the very best of Microsoft Azure’s security framework.